Additive Fertigung mit Tailored Fiber Placement

Tailored Fiber Placement, or TFP, is a new and highly disruptive technology for additive manufacturing of composites that utilizes a stitching technique to place fibrous materials in controlled paths. Traditionally, carbon fiber 3D printing has been investigated for its applicability in both prototyping and manufacturing of composite parts.

However, 3D printing methods such as fused deposition modeling (FDM) with embedded carbon fiber filaments is a slow process often with a low fiber volume fraction (FVF) that can be prohibitively expensive when used for medium sized parts greater than a few volumetric centimeters.

Additionally, thermal profiles in carbon fiber 3D printing can cause significant warping while being harder to tailor for mechanical optimizations of the material. TFP removes many these complications and drawbacks.

Additive manufacturing with TFP is an additional tool for the composite designer that allows increased control over mechanical properties such as fiber orientation, drapability, thickness, and other material optimizations. By using three dimensions of stitching placement and additively layering materials, composites with high fiber volume fraction can be quickly produced with minimal waste material. Existing molding can often be used with this process further reducing the initial exploration and production costs.

Material freedom

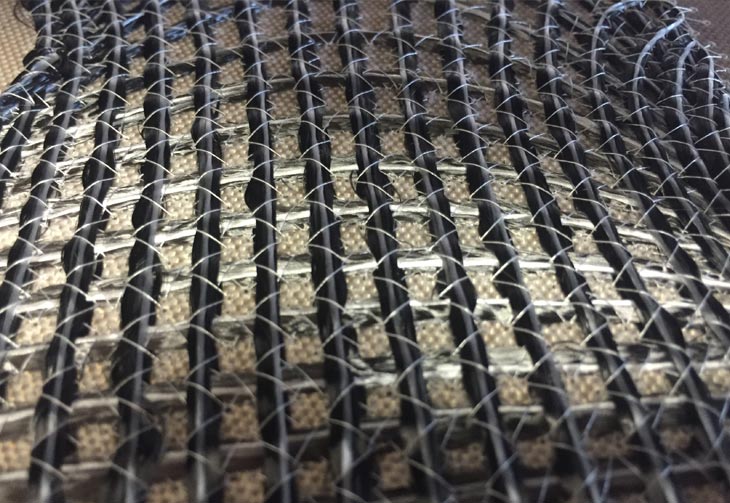

3D fiber-reinforced stitching allows for a wide range of materials to be used both with the composite fibers and also as supporting matrix materials. By using fiber tow directly from the manufacturer, additional cost can be saved by not relying on other textile processes such as weaving. Thermoset and thermoformed materials can easily be accommodated as well as material changes throughout a single preform.

Verschiedene Materialien können in einer Preform verstickt werden, um Steifheit, Drapierbarkeit und andere mechanische Eigenschaften anzupassen.

Multiple fibrous materials can be used in the same preform. This can allow for complex areas of localized stiffness. Cheaper materials like glass fiber can be used to create areas in a preform to hold shape, while more expensive materials, such as carbon reinforcement, occur only in localized areas where they are most needed mechanically. Additionally, the same machine setup can be used to run natural fibers, thermoplastic fibers, wires, and wide range of other materials, opening development possibilities for the composite designer.

Multiple companies are now investing in the creation of comingled fibers. These are engineered fibers consisting of carbon fibers that have been additionally mixed with various thermoplastic fibers in set FVF. This material behaves mechanically like a traditional fiber tow that can be placed by TFP machine, however consolidates quickly when heat and pressure is applied in an engineered mold. This process can allow for rapid molding and increased production.

Unlike many tape laying systems, TFP allows for circular reinforcement to easily be integrated into a composite part

Machine flexibility and freedom

Like most additive manufacturing technology, TFP machinery is easily reconfigured to be able to run different parts. Instead of purchasing customized equipment for each part in a composite design, the same machine can often be retooled to run a different material and design in under 10 minutes.

This allows the same production machines to maximize both their manufacturing and prototyping potential

Tailored mechanical support

Additive technologies, such as TFP, allow for the composite designer to optimize various mechanical properties of the part to the applied forces. Other 3D additive manufacturing processes often rely on short fibers to create the mechanical reinforcement. However, TFP maintains the carbon fiber tow allowing for long fibers to be placed in complex geometries increasing mechanical properties. Circular patterns can be used to mechanically reinforce holes, while unidirectional fibers can be placed in supporting regions to resist tensile loads. Other design techniques can be used to increase properties like toughness, stiffness, and localized crack resistance. Design and corresponding optimization possibilities are nearly limitless due to the ability to highly control the fibers orientation and placement.

Tailored drapability

As the preforms created with TFP maintain their compliant textile attributes, complex drapability can be engineered and built into the composite. By designing stitch lines in combination with areas of lower fiber density, complex bendable and foldable areas can be created. These origami-like structures can function to allow more complicated three dimensional design possibilities with little waste material.

Typical preform dimensions

TFP allows for material to be controllably placed in three axes. Standard machine sizes currently can accommodate parts 1.5 x 2 m with variable thickness of 0.1 to 1 cm per preform layer. In creative designs, this Z axis height can be used as ribbing in the composite to create improved stiffness while continuing to optimize material usage. Additional thickness can be created by stacking interlocking preforms in molds designed to build further height. TFP fits a specific size niche between tape laying machines for large parts, and 3D printing for smaller parts. The upfront cost of a TFP machine is considerably less than most tape laying machines and allows additional curvilinear fiber paths and complex drapability.

Scalability

TFP has an additional advantage over many other additive manufacturing technologies when it comes to scalability. Smaller prototyping machines for TFP can be used to create and test different preform geometries for various optimizations in early development. However, once the design is selected, additional production machines can quickly repeated those designs in scale in an automated manufacturing process.

Erste Designs, die auf kostengünstigen Einkopf-Prototyping-Maschinen entwickelt wurden, können für einen automatisierten additiven Fertigungsprozess schnell auf Produktionsmaschinen skaliert werden.

Conclusion

TFP has a place in the composite manufacturer’s toolkit, especially for medium sized parts or parts with complex loading or curvilinear patterns. The low barrier to entry with this type of additive prototyping machine allows for the composites designer to experiment with different material selections and tailorable placement options for mechanical optimizations. When a design is found to be acceptable, larger production machines can quickly scale that prototype into a manufacturable product and assembly line reducing manual processes like trimming. TFP is a powerful additive manufacturing tool for medium sized composite parts.