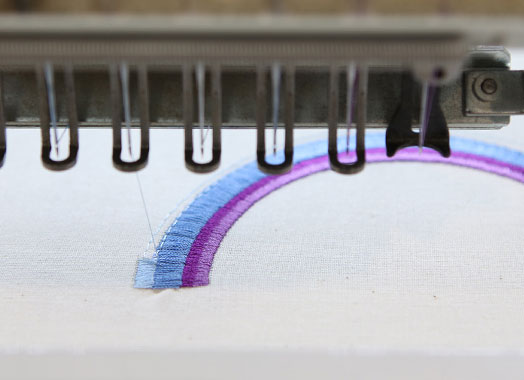

A major difference between a sewing machine and an embroidery machine is the capability to have a variety of colours (needles) per head. ZSK offers embroidery machines with 6, 9, 12, 18 and 24 needles. In general, one can say that a higher number of needles leads to reduced downtimes for changing of threads on the machine. Customers choose to have a higher number of needles to have more colours on the machine, to have a variety of thread types (i.e. very thin thread for sharp and crisp lettering and normal embroidery thread) or they choose a low number of needles in favour of space between the heads. Especially towel embroidery houses typically tend to have a low number of needles to roll up the towels in-between the heads. Certain ZSK models such as the 56 head machine are limited to 6 needles due to their head spacing.

The Right Strategy – the downtime in-between colour changes can be optimized with the right strategy. If a certain design is expected to be produced in a large volume, it makes sense to place the required thread cones next to each other, so that the path for the colour change motor is the shortest and quickest possible.

In larger production environments with often changing designs, colours are often placed at random on the machines. Many customers tend to block a certain number of needles for standard colours (white, black, red, blue, etc.). These colours are on the first needles and are never exchanged as they are used in the majority of designs.

Customers using devices on their machines (sequins, cording) have to constantly move the heads between needle 1 and i.e. 12. The time this process takes is a downtime. Therefore, designs should be digitized in a way, so that these changes occur as little as possible. In some cases these cannot be avoided. In 2018 ZSK introduced the Fast Colour Change in the Challenger and Racer II Series to offer a solution that reduces these downtimes heavily.

RACER

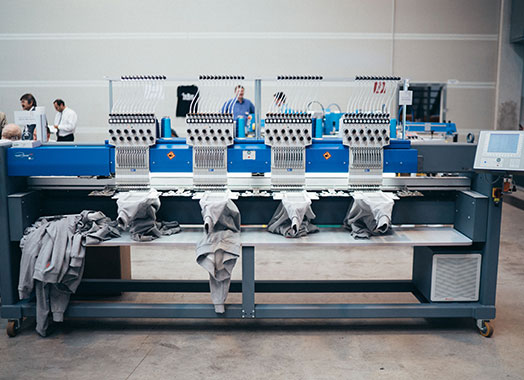

State of the art technology – With the embroidery machines of the new series RACER, we set again the world standard for tubular embroidery machines.

CHALLENGER

Our flat bed embroidery machines are the ideal means of production with which you can meet even the highest quality requirements of your customers.

Immer auf dem Laufenden bleiben

Newsletter abonnieren

Ihre Nachricht an uns