JGVA 0109 - Triple Embroidery Head System for Technical Applications

The embroidery technologies developed by ZSK TECHNICAL EMBROIDERY SYSTEMS, a division of ZSK STICKMASCHINEN enable a wide scope of products, applications, and methodical procedures to be implemented for specific design goals and constraints.

Jump to:

Introduction | Offer JGVA 0109 | ZSK Embroidery Technology | Downloads

Introduction JGVA 0109

The JGVA is designed as a highly capable and integrated Smart Textiles and Composites development center.

This advanced model can create anything any ZSK embroidery machine can do. It was designed with robustness in mind to help makers and creators flush out their design, as well as do small batch manufacturing for timing studies.

This machine is a powerful platform to stitch circuit boards, embroider wires, place sequins, create soft bioelectric sensors, and create composite parts.

The JGVA 0109 -500 (700)

Move the cursor to the yellow points for info.

JGVA 0109-550 (700)

Universal portal embroidery machine with three different embroidery technologies:

- 1 x W-head with one needle to apply and fixate wires, fibers, optical fibers etc..

- 1 x K-head for chain and moss stitch with automatic colour change for 6 colours.

- 1 x F-head, a standard embroidery head with 9 needles and colour change.

Head distance

Between the heads: 275 mm / 10.8"

Embroidery fields (Width x Depth)

Using all three heads: 550 x 600 mm / 21.6" x 23.6"

W-head only: 1.100 x 600 mm / 43.3" x 23.6"

K-head only: 875 x 700 mm / 34.4" x 27.5"

F-head only: 550 x 700 mm / 21.6" x 27.5"

T8-2 Control Unit

Machine control unit with Windows CE.

8.4" TFT colour monitor.

3 x USB 2.0 ports.

1 x RJ45 Network port.

Internal memory for pattern parameters.

Data output for optional MY.ZSK production data acquisition.

Embroidery Speed

- W-head: 800 stitches/min., depending on thread quality, design and machine parameters

- K-head:

- Chain stitch - 700 stitches/min.

- Moss stitch - 650 stitches/min.

- F-head: 1.000 stitches/min., depending on stitch length and material

Installation and Training

We help and support you throughout the whole process of setting up your machine and teaching you how to use it!

Quality Control

- X hours of factory testing and break in use before shipping to ensure quality.

- Machine installation with ZSK expert.

- System setup with demonstration fabrics and materials.

- Full system check

- Quality-assured runtime for calibration and shipping

Technical Data

Dimensions fully assembled

Length: 3.450 mm / 135.8"

Depth: 1.840 mm / 72.4"

Height: 2.200 mm / 86.6"

Weight: approx. 1.150kg / 2535lb

Power supply voltage: single phase AC 230 V.

Dimensions without table, T8 and active supply unit

Length: 3.270 mm / 128,7"

Depth: 1.600 mm / 63"

Height: 1.740 mm / 68,5"

Dimensions without strut, table, T8 and active supply unit

Length: 3.270 mm / 128,7"

Depth: 1.460 mm / 57.4"

Height: 1.740 mm /68,5"

Please note:

- The machine can work with a 120 V to 230 V transformer.

- If pneumatic wire-/fiber trimmer, automatic bobbin changer or pneumatic clamping- and tensioning device will be installed, compressed air pneumatics are required. A compressor is not included in the scope of supply. A small pancake compressor will work fine.

Info: US doorways clearance (without guarantee of correctness)

Standard front door: 31" of clearance.

Standard interior door: 33" of clearance.

Standard back double door: 66" of clearance.

Light Barrier at top

Light barrier at front of the embroidery heads

Twin Active Supply Unit

The Twin Active Supply Unit for wires and fibers with standard motors can be installed on each laying head. Each supply system can take wire or fiber rolls up to 10kg. A new function implemented detects the end of supplied media.

Conversion Kit

Conversion kit for the supply of wires or fibers from the active supply unit to the ZigZag layer.

Conversion Kit Small reel

Conversion kit small reel to feed wires / fibers from a small reel, which can turn unlimited around the needle as an alternative to an installed active supply unit. Not applicable in connection with wire/fiber changer and ZigZag layer motor outside of the head.

W-Bobbin Winder

Winder to rewind wire or fiber strings onto small rolls for the ZigZag layer for the W-head.

Wire Hit Detection System

If a laid wire is hit by the needle the machine stops and indicates the affected laying head. The defective part can be marked to be removed. In many branches like in the production of car seat heating systems this function is obligatory.

Automatic Unwinding of Z-Axis

If wires / fibers are supplied from an active supply unit via pipes to the ZigZag layer the maximum rotation is limited to 360°. This option allows to adjust at what degree of the Z-axis an automatic unwinding shall be executed.

Layer feet

Three different layer feet each for wire and fiber

Carbon protection

All electronic devices of a ZSK technical embroidery machine can be protected against carbon dust.

Auto Select Bobbin Changer for F-head

Auto Select Boobin Changer for F-head with a magazine for 8 bobbin cases, including bobbin cases and bobbins. The Auto Select Bobbin Changer enables the allocation of any bobbin case of the magazine to a specific needle or a singular access.

Upgrade Kit Thick Yarn

Additional thread tension and other picker for thick thread

Special Eyelets

F- and K-head: eyelets for special threads

Special Gate

K-head: special gate for conductive yarns.

EPCwin 7 Digitizing Software

EPCwin is the standard software for technical applications on embroidery machines.

The software offers i.e.:

- CAD drawing functions,

- Excellent solutions for team work,

- Switching between the various ZSK technologies,

- Change machine settings flexibly during the embroidery process.

Installation

Installation of EPCwin 7 by ZSK experts

Training

- Technical drafting and drawing for digitizing

- Basic EPCWin 7 course

- Intermediate EPCWin 7 course

- Advanced software training courses (by appointment only)

Knowledge and Consultation

Our support and training courses are unparalleled and our technical staff has years of previous experience at companies that design circuits for spacecraft, tech companies that design flexible electronics, and state of the art medical device companies. We enjoy pushing the bounds of what can be made with technical embroidery!

Courses include:

- Introductory machine and operator training

- T8 machine controller training

- Intermediate and advanced smart textiles training courses

- Intermediate and advanced composites training courses

- Production manufacturing and optimization training course

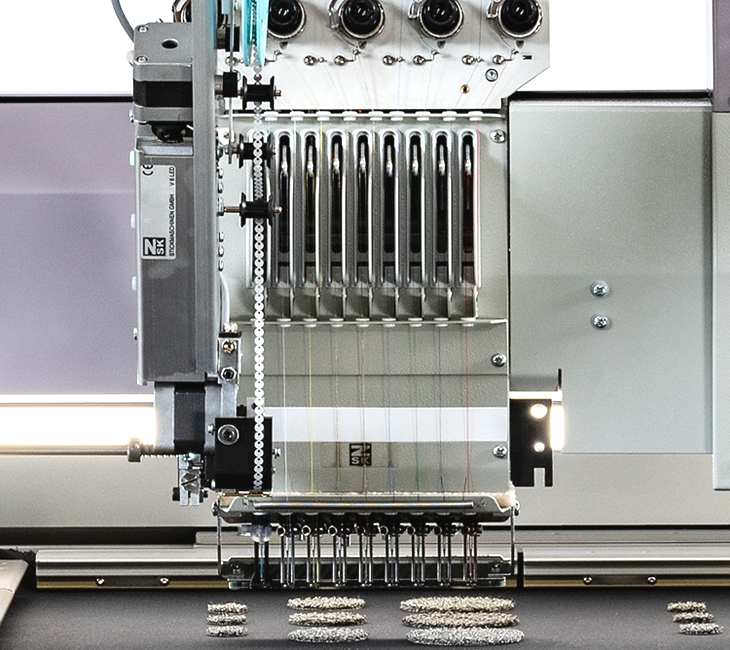

The F-Head

The F-head is the most commonly used embroidery technology, often referred to as standard embroidery.

By using this standard technology with a satin- or running stitch with conductive threads, many applications for wearables, e-textiles and smart textiles are possible.

The F-head of the JGVA offers 9 needles or space for 9 different yarns.

The K-Head

The K-head creates moss embroidery. This single thread system creates loops at the surface of the carrier material. Voluminous surfaces will be generated by the compact placement of the stitches.

An actuator system with four separate single motor units supports the customization of parameters like the height of the loops, the presser foot or the inclined position to satisfy required needs.

Moss embroidery associated with electro conductive yarn is the ideal combination for products from the fields of smart textiles, wearables and medical textiles.

The W-Head

The W-head allows the laying of fibers, wires, and tubes onto a textile or a flexible carrier material. It is the most versatile embroidery technique allowing for strange (like biomaterials), thick (like ethernet cords), or stiff materials to run that are too large or too delicate to run as threads.

Embroidery technologies like the tailored wire placement, tailored fiber placement (TFP), and tailored tube placement can be realized with this technical head. This head is extremely popular with composites customers looking at creating carbon or glass fiber preforms and inserting electronics and wires into them, as well as Smart Textiles customers who want to have the maximum material exploration possibilities with technical embroidery.

Whitepaper

A Guide to Technical Embroidery

A paper written by Dr. Topher Anderson to support finding the right additive textile manufacturing equipment for your business needs