Bobbin Changer for Flat Embroidery Machines – Minimizes Downtime and Maximizes Efficiency

Increase productivity by up to 15 % - with our bobbin changer system (SKW) you can increase the efficiency of your flat embroidery machine enormously. We have developed the well proven SKW in practice especially for our high performance flat embroidery machines. It eliminates the downtime that previously arose when changing the lower thread bobbins.

Example Calculation for Increasing the Efficiency when using the SKW System

| Machine: | YCF 4405 |

| Embroidery: | All over within the pull-through process |

| Passages: | 2 hours |

| Passages per shift: | 4 passages |

| Layers: | 2 layers per day |

| Bobbin change: | 8 minuts with 2 Leuten |

Productivity without SKW system:

| Standstill per hour: | 8 minutes |

| Standstill per pass: | 2 x 8 min. = 15 minutes |

| Standstill per shift: | 4 x 15 min. = 60 minutes |

| Standstill per shift: | 2 x 60 min. = 2 hours |

| Production time net: | 14 hours (2 hours standstill) |

| Productivity: | 8 lanes |

Productivity with SKW system

| Downtime for bobbin change: | none |

| Time gain per day: | 2 hours |

| Production time net: | 16 hours |

| Productivity: | 9 lanes |

Production has increased by 15 percent!

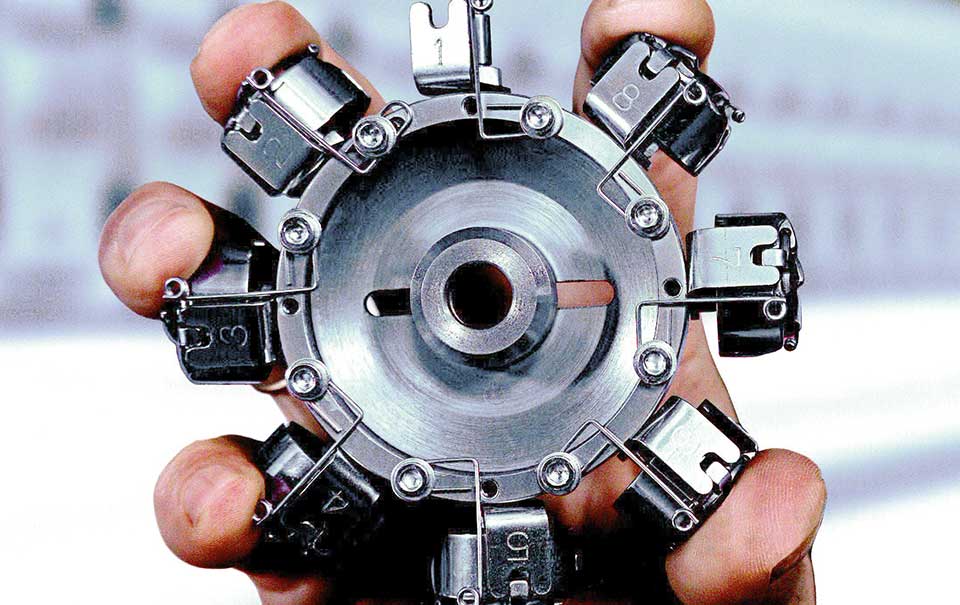

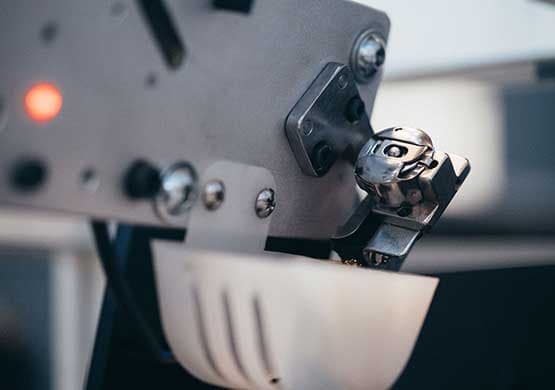

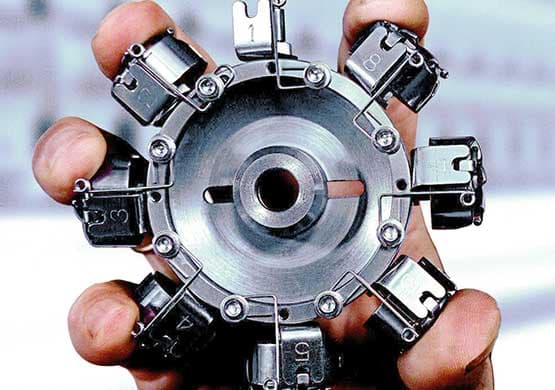

New Potentials through Automatic Assignment

We offer the bobbin changer in three versions: as 1:1 changer, as standard version and as Auto Select bobbin changer. The Auto Select bobbin changer knows the position of the magazine at any time. In the T8-2 control unit, the needle and bobbin and thus also conductive top and bottom yarn, thick top and bottom yarn for 3D effects as well as the same color top and bottom yarns can be automatically assigned. This offers new potential, especially in high-end design. Production times are shortened and possible mistakes in a manual change of bobbins - to keep the yarn colors of top and bottom yarn in an embroidery equal - can be avoided. Even with the combination of thin and thick top yarn in a pattern, the Auto Select bobbin changer is a great help.

The bobbin case changer can be installed on all ZSK flatbed machines, with the exception of the RACER machines, as access to the free arm for the textile is required.