CHALLENGER - Our New Royal Class

No matter if your focus is on flat or ready-to-use embroidery - our flat bed embroidery machines are the ideal means of production with which you can meet even the highest quality requirements of your customers. Designed for efficient production in borders or single frames, the range of machines ranges from 10 to 15 heads with 9 or 12 needles, which are controlled and driven by the new control electronics MCP 35, latest absolute encoders and powerful servomotors.

Precision in Continuous Embroidery Operation

Reliable embroidery machines Made in Germany

Our ZSK embroidery machines combine features that were previously difficult to reconcile: highest precision in the embroidery image and absolute reliability in continuous embroidery operation.

The sturdy construction and specially developed vibration dampers ensure that the machines run with low noise and vibration even under maximum load. Extremely large embroidery fields in conjunction with the highest embroidery speed result in enormous productivity. Developed and manufactured in Germany, our flat bed embroidery machines guarantee the shortest payback period through immense speed, accuracy, and flexibility as well as proven longevity.

The Main Features of the CHALLENGER

Embroidery speed 1,100 stitches/min.

10, 12 and 15 heads

Up to 12 needles/colors

New control electronics MCP 35

Servo motors of the latest generation

Absolute encoders

Adjustable frame limitation

Automatic thread cutter

Energy-saving LED light strips

Upper and lower thread guard

Automatic reverse embroidery function

Height-adjustable fabric presser

Automatic head selection

Technique for continuous designs on endless fabrics

Low noise

T8 control unit

Integrated design editor

Accepts all common industrial embroidery codes

Storage for approx. 80 million stitches

Automatic error analysis

Windows based networking

Built and designed for 24/7 production

High value retention

Made in Germany

Options and Accessories

Our ZSK embroidery machines can be optionally extended by the integration of additional equipment.

Machine Options

- Cord/loop device

- Cording device ZigZag EP 1.2

- Pearl device

- Boring device

- Sequin device

- HAC – Hot Air Cutting device

- Automatic lower thread change SKW 1-1

Advantages of the CHALLENGER series

The main advantage of the CHALLENGER series is the use of servomotors instead of stepper motors to move the pantograph. The servomotors generate higher and constant torque, resulting in increased performance, efficiency and stitch quality.

The servomotor results in reduced noise when moving the pantograph and a much smoother motion.

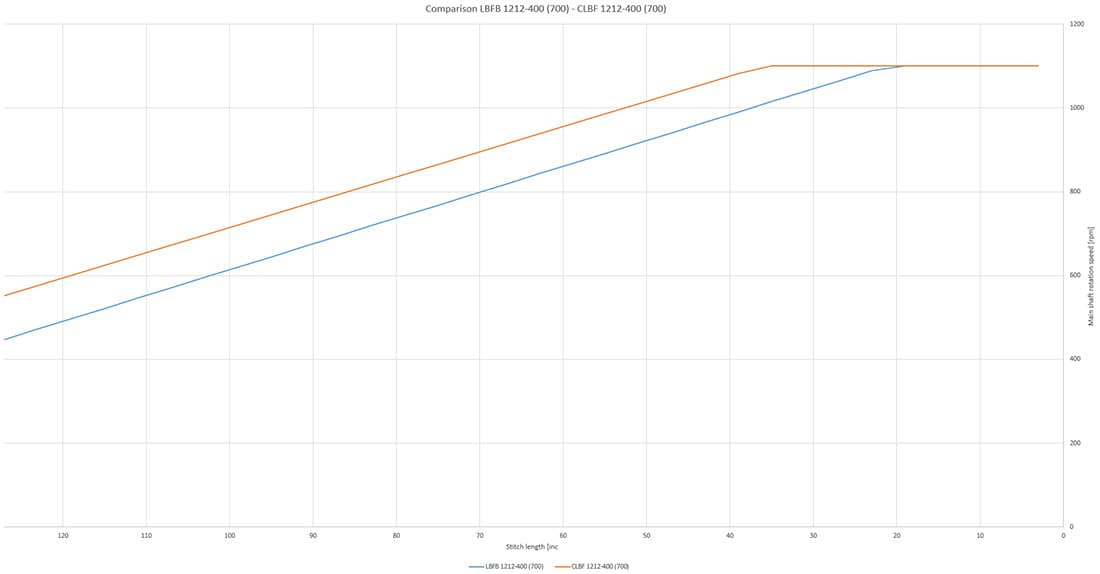

Figure 1 shows a comparison between a LBFB 1212-400 (700) and a CHALLENGER CLBF 1212-400 (700). The CHALLENGER series offers a maximum speed of 1,100 rpm up to 3.5 mm stitches, while the LBFB 1212 reduces the speed at 1.9 mm stitches. With an average design with a reasonable number of longer stitches, the CHALLENGER series offers increased performance of approximately 10 %.

Further information can be found here: PDF Comparison

All CHALLENGER machines are equipped with LED lighting. Comparing a CXCF 1512 with an XCFB 1512 results in energy savings of approximately 750 kWh (24/5 operation, 50 weeks per year) in the CHALLENGER machine.

From the beginning of 2019, the CHALLENGER series will offer a new and optional color change that reduces color change time by up to 75 %. The standard CHALLENGER series already offers an improved color change time of about two seconds per process compared to a standard ZSK flat machine. The CHALLENGER series is equipped with a faster catcher motor and the speed of the last stitches before a color change and the first stitches after a color change have been improved.

All CHALLENGER series machines with 1,000 mm or larger stitching are equipped with 600 mm table cuts to give the operator greater access to the embroidery head. Other table designs can be offered on request.

The construction of the support bars under the table tops has been changed. The new design allows more free space for the operator, free under the machine and faster when changing bobbins.

Challenger machines are equipped with MCP 35 electronic cards. This allows for regular T8-2 software upgrades with the latest features.