ZSK Vision System – The Solution for Different Tolerances

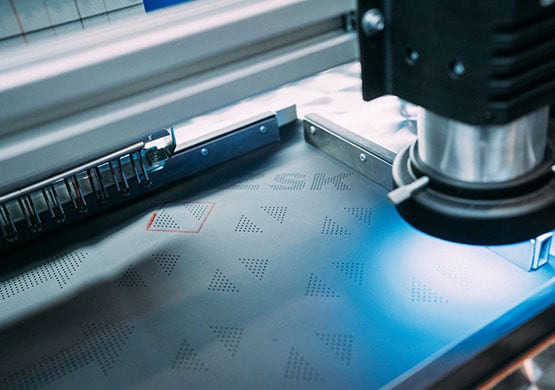

With our ZSK Vision System for single-head embroidery machines, we offer a unique solution for placing your design. The camera system has been specially developed to meet tolerances of approx. +/- 0.3 mm. The camera system is required when you want to position embroidery or quilting perfectly as your material changes slightly during the embroidery process. A typical requirement is a perforated leather part in the automotive industry. Leather behaves differently depending on material thickness, temperature and lacquer. Embroidery or sewing on the material causes the material to contract. If seams are to be placed with high precision, the workpiece must be re-measured aftr each seam to ensure that the seam is in the desired position.

Use with Single-Head Embroidery Machines

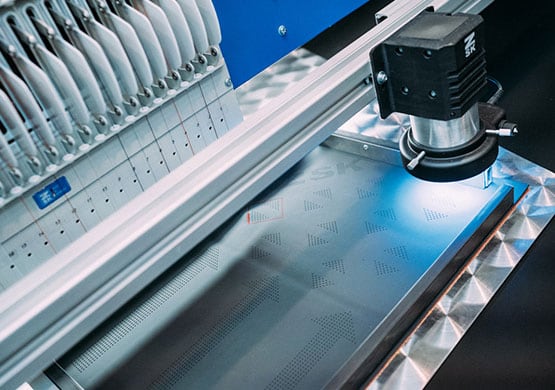

Our ZSK Vision System can be installed on our single-head embroidery machines with MCP-35 and servo motor. Single-head machines are the only way to overcome different tolerances. Our servo-controlled CNC machines can be programmed with the CAD system EPCwin. This loads DXF files and creates both the sewing file and the ZEPL file to control the camera system.

The ZEPL file provides for process automation. The ZEPL file can only be programmed with EPCwin and ensures that the camera controls the right positions on the workpiece.

To ensure the right positioning of the workpiece in the machine, we recommend a suitable frame where ideally the workpiece is picked up on pins.

Data Adaptation in Real-Time

By using our ZSK Vision System, you can also compensate for tolerances resulting from previous processes, shrinkage during the embroidery process or linear expansion. It checks the actual position of the perforation holes during the embroidery process and can adjust the embroidery data in real-time.

Important to note is the limitation to linear changes. If leather is glued to foam by hand and pulled by hand, the positioning of the perforation does not change linearly. Such changes cannot be compensated by a vision system.

OPS 1 versus OPS 2

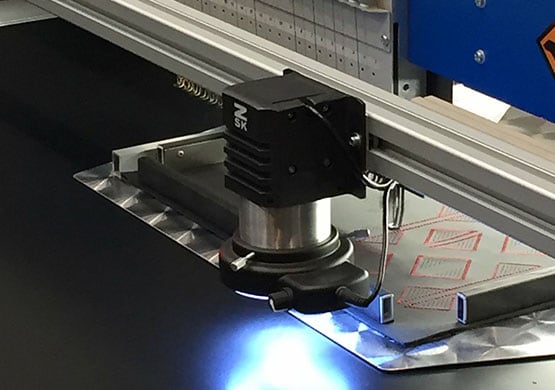

OPS is the development designation for the vision system and stands for Optical Positioning System. With the two systems we distinguish the complexity of the requirements.

OPS 1 detects elements, e.g. on a woven ribbon, positions a pattern with the corresponding x and y coordinates, and rotates the pattern if needed.

OPS 2 detects two points, colour differences or material differences. On this basis, the positioning is calculated and the pattern can be stretched or compressed.

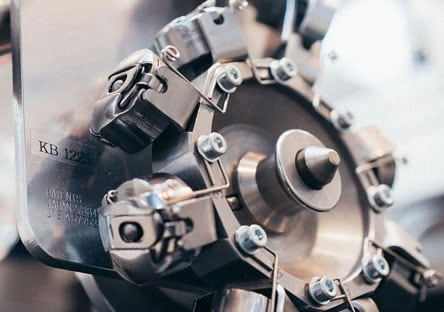

Combination with bobbin case changer

The Vision System easily cooperates with ZSK accessories. If a product is to be provided with sewing or embroidery, this can be controlled by the Vision System. The AutoSelect bobbin case changer of the embroidery machine simultaneously ensures the selection of the correct bobbin thread and the bobbin case with the correct tension.

Consulting and sampling

The success of any project requires the right preparation. The ZSK embroidery studio is equipped with sampling machines including the ZSK Vision System. ZSK supports customer projects from prototype development to series production.

If you are interested in further information and if you would like to gain experience, please send us your workpiece and DXF file. We support you with sampling and cycle time analysis on our machines, and we also offer individual frame construction.

Case Study - Rühl Leder

Rühl Leder, a long-established company based in Mülheim an der Ruhr, Germany has been one of ZSK Stickmaschinen’s customers since mid 2018. In the …

About Leather Embroidery

ZSK embroidery machines are known since decades to be workhorses and very strong and precise on heavy materials ...