Maximum of Automatization and Efficiency– Innovations of Technical Embroidery

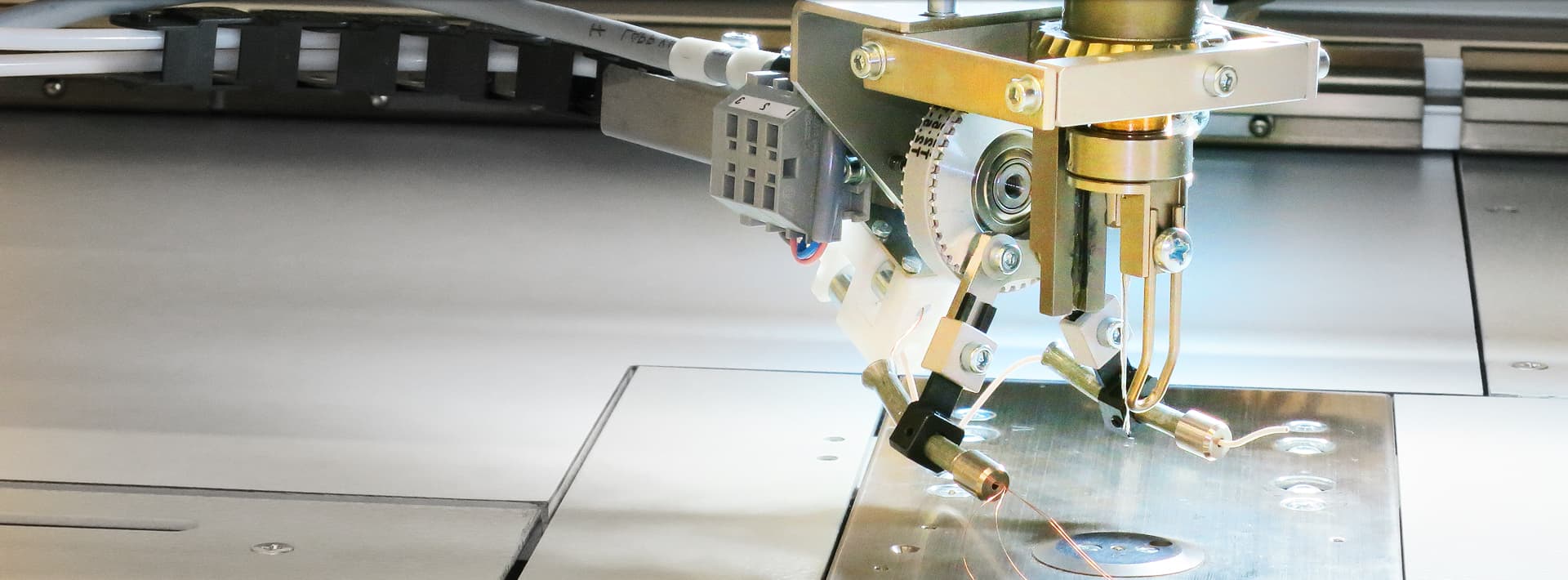

With great expertise and experience in the textile machine construction, we have developed our so-called ZSK technical embroidery systems. These machines enable the free orientated laying of fibers and wires in a 2-dimensional space on flexible carrier material – even accordingly to the distribution of forces within a structural component, known as Tailored Fiber Placement (TFP).

Embroidery that Creates Connection Paths

With innovative applications like active wire and fiber supply systems, automatic pull-through systems for the carrier material or wire hit detection our technical embroidery systems achieve a top level of automatization and efficiency. Our technical embroidery systems are designated to lay wires, fibers or tubes on a fabric and place them in any shape required for e.g. sensors, heating systems, conductive paths, structural reinforcement integrated in any textile structure. Some examples for the application of this technology for Wearables, Smart Textiles and E-Textiles are sensors (temperature, moisture, stretch) or heating systems as well as fine wire areas as connectors for electronics or signal transmission.

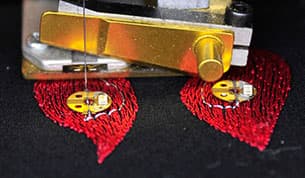

Other technical embroidery technologies can be used to embroider conductive threads. Wearables, Smart Textiles and E-Textiles applications are e.g. textile electrodes in different required shapes and structure or conductive paths or pads for the connection between electronic and textile. By using an attachment for functional sequin devices, sequins with LEDs can be automatically placed on a fabric or garments as well as on baseball caps. The contact of the LED sequin and connection paths will be done by embroidery of conductive threads.

Podcast - Technical embroidery is a massive field of opportunity

In conversation with Dr. Topher Anderson, Technical Embroidery Manager, ZSK USA on the great possibilities that technical embroidery systems offer.

TECHNICAL EMBROIDERY

The ZSK TECHNICAL EMBROIDERY SYSTEMS Magazine

The magazine is a collection of articles on the subject of technical embroidery that have previously published in the ZSK customer magazine "CARL".

Automotive Solutions

Cars, motor homes, boats or airplanes – since decades, embroidery technology adds a refined touch to their interior by placing logos on headrests and carpets...

Tailored Fibre Placement

Cost cuts, less wastage and reduced manufacturing times – with our development of Tailored Fibre Placement (TFP) you can overcome a lot of ...

Tailored Wire/Tube Placement

Embroidery does not only overcome the challenge to improve textiles' optical properties, you can also add various functions to your products by using ...

E-Textiles

E-textiles or the ability to embed electronics and their electrical properties in fabric create a new class of distinct materials. They offer you the ...

Moss Embroidery

Their versatility and commitment to eclectic signal types and biometrics make moss embroidery an important method of collecting biomedical signals from ...

Functional Sequins (FS)

Whether integrated LEDs, thermal sensors, RFID chips, antennas, Bluetooth chips or even entire microcontroller circuits - functional sequins (FS) ...

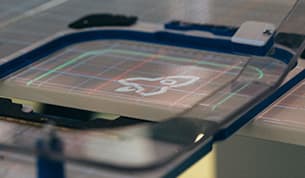

Vision System

With the ZSK Vision System for single-head embroidery machines, you can overcome different tolerances and achieve perfect results...

Innovations

Can you imagine that the use of embroidery machines goes far beyond the familiar application of textile finishing? Let yourself be inspired ...