Chenille Machines – Innovative Possibilities through Moss and Kettle Embroidery with K-Head

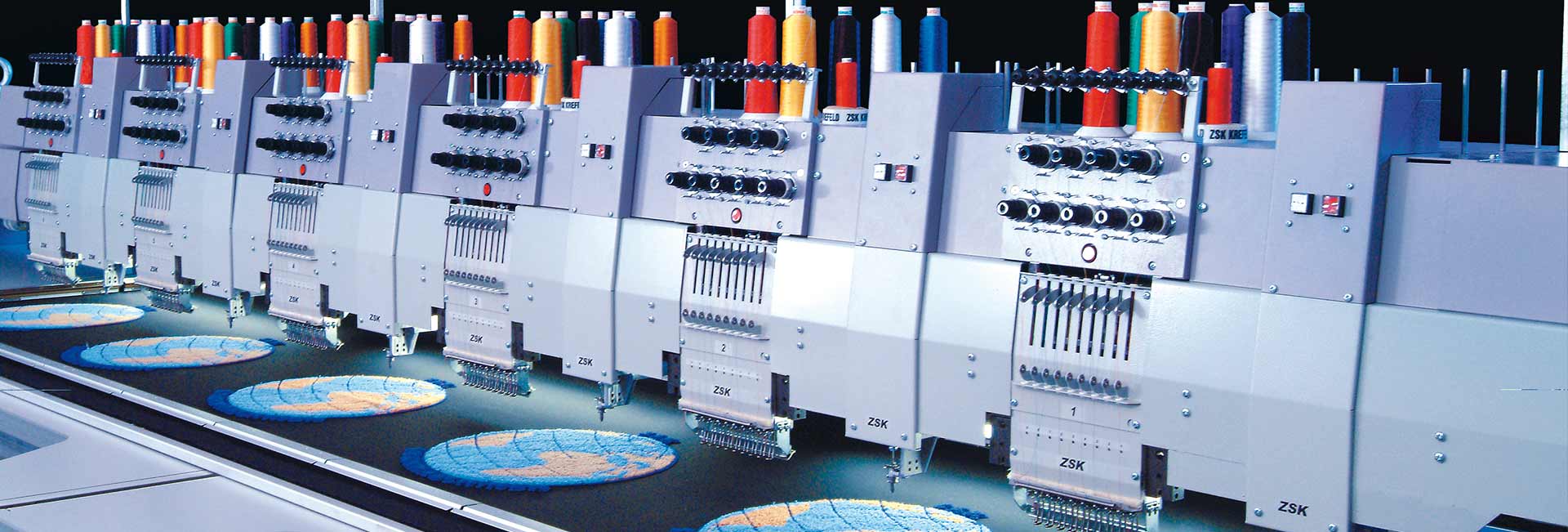

Control and drive concept make our Chenille machine products with innovative power. These K-head machines are designed for sophisticated moss and kettle-embroidery. The head is a special design embroidery head with only one embroidery needle. The drive concept with four individual stepper motors per embroidery head allows individual variation of the main functional elements needle, fabric presser and thread leveler. It is the basis for both high quality and productivity in moss and chain stitch embroidery.

Creative Diversity

With the aid of the control, for the first time a comfortable, fast and reproducible adjustment of the machine to the different influences, such as e.g. embroidery thread, embroidery base and pattern possible. An automatic color changer for up to six colors and height-adjustable moss loops offer further variety in the design.

Fine Kettelstich embroidery with our ZSK-K embroidery head

Moss embroidery with high loop density with our ZSK-K embroidery head

Moss embroidery and Kettel steach framing with our ZSK-K embroidery head

Moss / Kettel embroidery with our ZSK-K embroidery head and the sequin device

Combination of Embroidery Styles

Surprisingly New Embroidery Designs

The K-head can be linked to the standard embroidery head and the W-head.

This combination of embroidery styles within a pattern opens up new possibilities for you to combine both embroidery techniques to surprisingly new embroidery images. All machines of the special series can be additionally provided with a sequin unit. Thus, the already innovative possibilities of special purpose machines expand again.

Moss and Kettel embroidery using our ZSK-K head to create the design with exceptional feel

H-Series: Our ZSK-K embroidery head with a standard embroidery head for multi-colored embroidery combines to create exceptional designs.

The combination of K, W and standard embroidery heads for multi-colored embroidery for almost unlimited possibilities.

Download

Sample Book K-Head: Moss and Chain

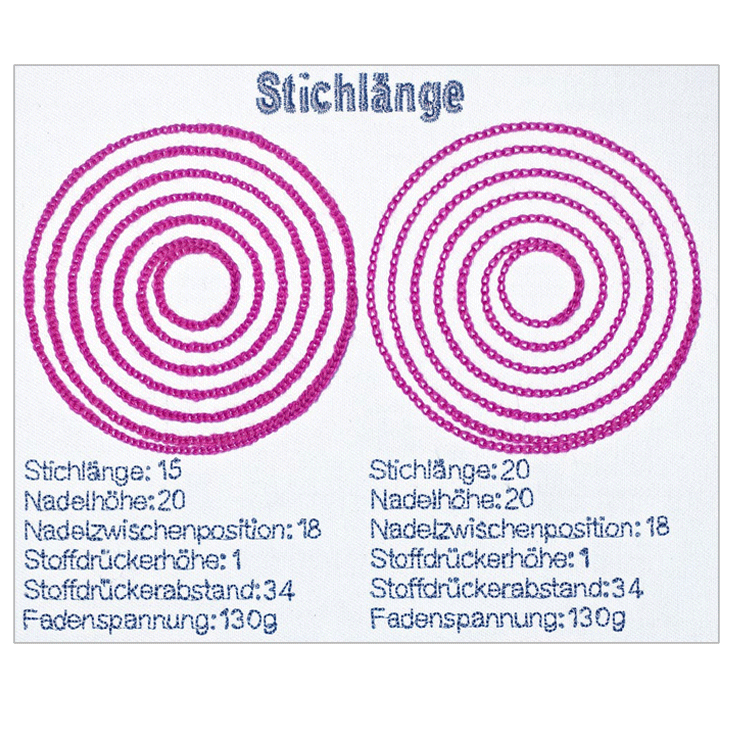

Settings and optical effect

Sample book to illustrate the influences of stitch length, needle height, intermediate needle position, presser foot height, presser foot spacing and thread tension for moss and chain stitches with the ZSK K-head.

Download: >> Sample Book K-Head

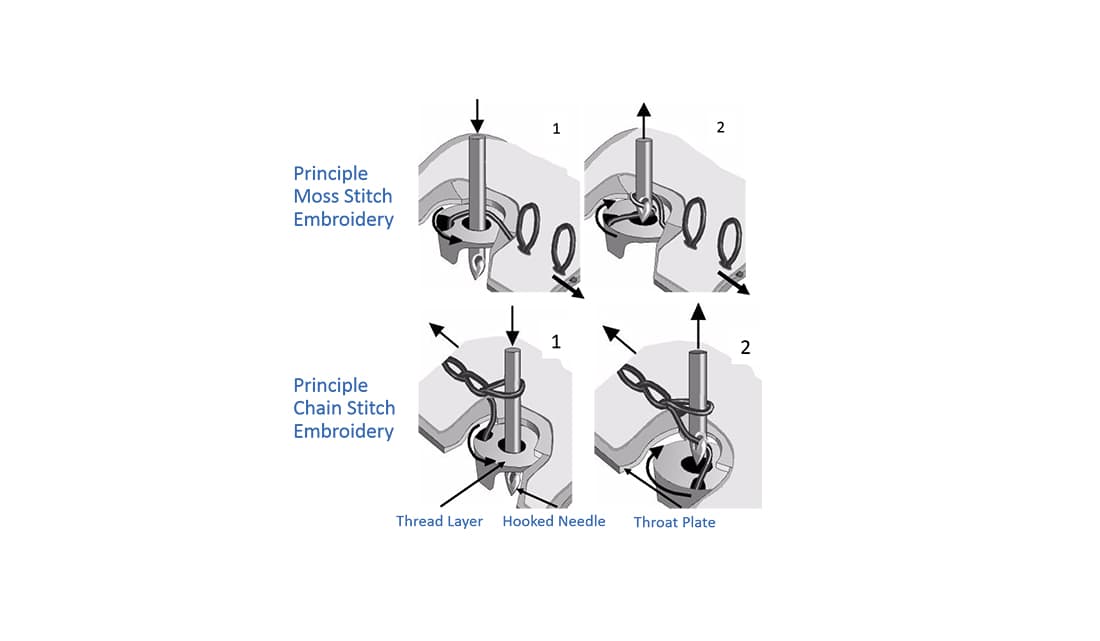

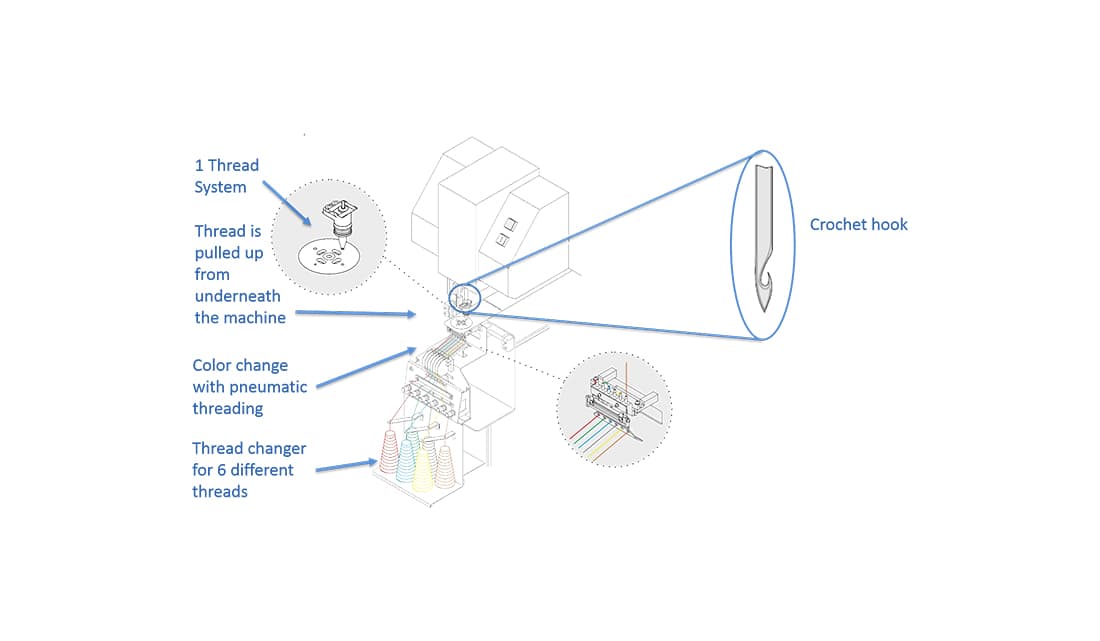

Principle of the K-head

• 1-thread system with hook needle

• Thread changer under the machine table

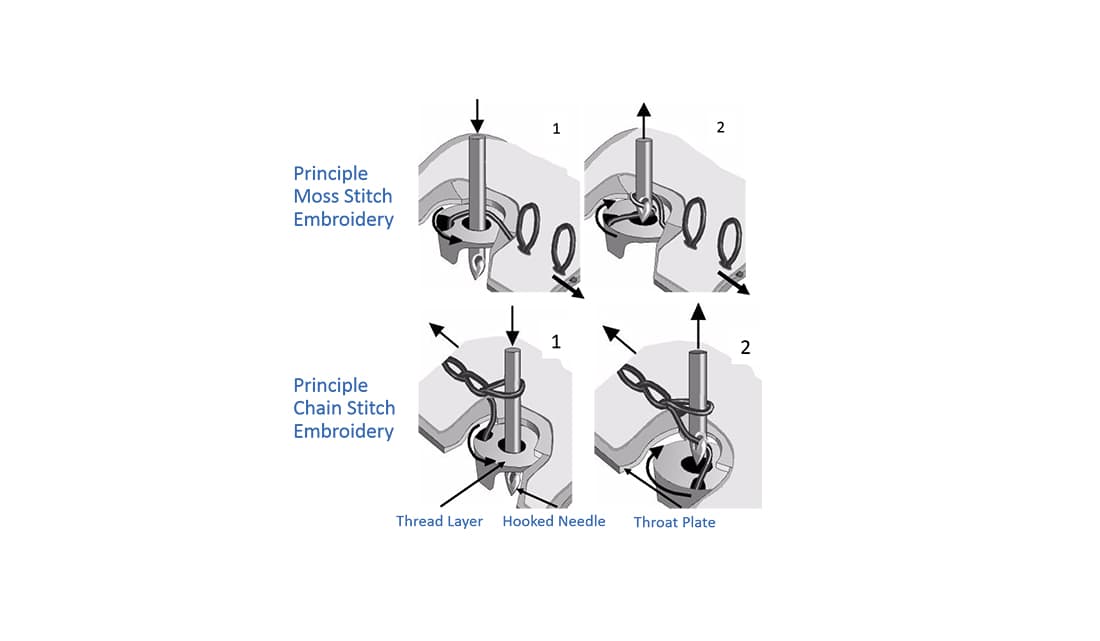

The moss embroidery is most likely to be compared with crochet. Moss embroidery machines are built differently than traditional embroidery machines, but use a similar embroidery technique. Moss embroidery is created by a one-thread system. In this system, the needle passes through the substrate and pulls the thread under the needle with the plate side upwards. Then, a loop is generated by a rotational movement of the needle on the upper side of the carrier material. The repetition of this pattern creates a dense, moss-like surface.

The illustration "Principle Moss Stitch Embroidery" (s.u.) clarifies this.

1. The hook of the needle points towards the embroidery direction in the direction of seam formation

2. Looping that build up on the surface of the textile for building a three-dimensional structure on the surface

The kettle embroidery is produced like the moss embroidery with a K-head, whose technical basis here is a one-thread system. In contrast to moss embroidery, the hook does not point towards the needle but in the direction of embroidery and thus also against the seam formation.

The diagram "Principle Chain Stitch Embroidery" (s.u.) illustrates this.

1. The hook of the needle points in the direction of the embroidery direction opposite to the direction of the seam formation

2. A continuous series of interlaced stitches forming a chain The kettleembroidery is often in the form of a framing of a moss stick area use