Efficient Solutions for Industrial Embroidery – Highest Quality for all Applications

With our machines and their possible options, we cover all the requirements of industrial embroidery. There is hardly a challenge of industrial embroidery that you can not master with our machines and their options. We have equipped our products to meet all requirements: from the wide range of machines used in contract finishing, to repeatable sample production for the furniture and home textiles industry, to specialized solutions for the automotive, mattress and workwear industries and promotion industry. In production, however, not only the flexibility and basic suitability count, but above all reliability and efficiency. Therefore, our machines have been specially designed and manufactured for 24-hour operation seven days a week.

You are well informed about all processes of your production through the use of our software solution My.ZSK. Which machine is how busy? What was produced in which time? What disorders were there? You can use My.ZSK to retrieve many evaluations that answer these questions. Mailed alarms for individually defined events as well as the possibility to analyze machine, head and needle disturbances show the chosen path towards predictive maintenance.

From single-head machines for the production of batch size 1 to the 56-head machine for volume production - we meet almost all requirements, even in the most demanding areas of contract processing.

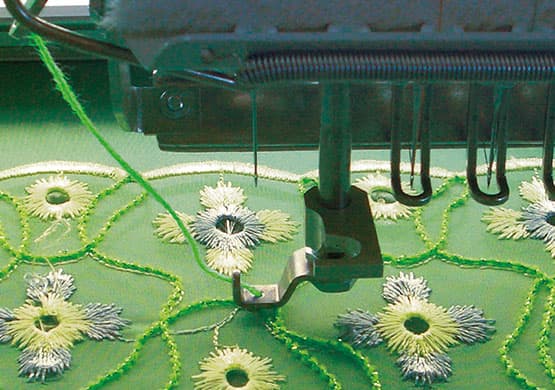

When it comes to the production of repeatable patterns, the processing of different yarn counts, the embroidery of thick fabrics to leather or the decoration with cords and loops, our ZSK embroidery machines are the optimal solution. They master all tasks with flying colors - around the clock.

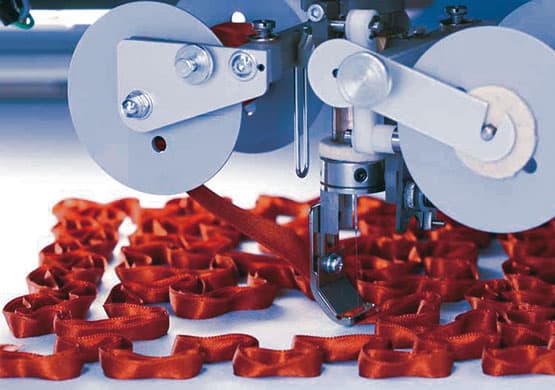

They form the basis of textile individualization: Machines that know no bounds to implement current fashion trends, and that can be expanded in order to be able to process the latest materials in the future. Sequins, rhinestones, cords and loops as well as pearls can also be embroidered in a quantity production.

The furniture industry places high demands on turning workpieces into products with a special look. These can fulfill our embroidery machines. By producing rapport-consistent patterns, processing different yarn counts and embroidering thick fabrics and leather, you can give furniture an effective look.

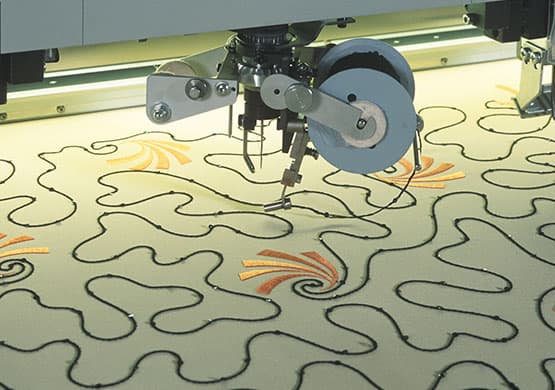

Our ZSK embroidery machines support a few process steps in mattress production. Even mattress belts that need to be precisely positioned and firmly cramped with the mattress can be processed with our solutions.

In addition to the rapid development of technical embroidery in the automotive sector, our ZSK embroidery machines are used primarily in the interior sector. This way, different yarns and colors can also be embroidered on leather. The special feature: You can even embroider patterns that allow only minor tolerances as part of larger patterns.

In the passenger compartment of the car, the smallest deviations from distances quickly become noticeable - the more so the closer the seams are to one another. Fabrics and leather, which can shift or slightly distort during the embroidery process, increase the problem. With our camera solution, this does not happen at all: Vision Eye constantly determines the position of the substrate (e.g. leather) with the current pattern progress and, using spacings in the Punch software EPCwin, realigns the substrate in real time - in a fraction of a second. The automatic optical control and correction ensure the exact parallelism of seams.

Individualized work clothing according to corporate identity (CI) is a special expression of the external presentation of companies. These companies are increasingly in demand for textiles that not only reflect the CI, but are also embroidered with the name of each employee. This balancing act between the serial production of CI-compliant workwear on the one hand and its individualization for each employee on the other hand master our machines with maximum efficiency. Machines with head deactivation and the supporting software EPCwin are then building blocks of this solution.

Heavy fabrics, yarns of different thicknesses, the laying and fixing of cords - embroidery machines have to meet certain requirements for the artful embroidery of flags. Our solutions meet these requirements and ensure high-quality results.

The production of small series with high flexibility, supplemented by the possibility to embroider also bulky and unwieldy goods, make our ZSK embroidery machines the first choice in the area of promotion. Thus, with the newly developed SPRINT 7, suitcases or golf bags can now be individually embroidered.

Emblems and badges usually place very high demands on the accuracy of the embroidery, as the motifs are to be displayed in true detail. On our machines, the carrier material can be fed from a roll. So that the first and last emblem have the same high quality, our specially developed camera solution Vision Eye is used. It provides a constant control of the pattern position relative to the embroidery head and any required correction in real time.