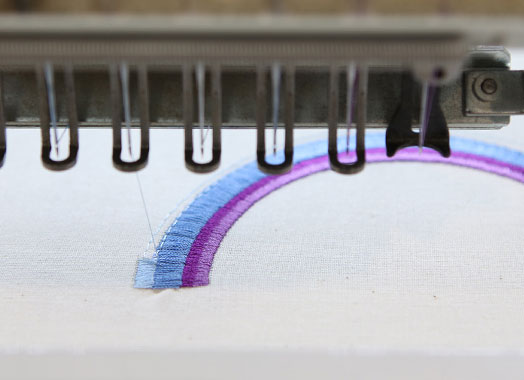

Since companies offer solutions for dying yarn outside the embroidery machine, we have seen customers wondering about sublimation as a cost-effective alternative. Sublimation is a low cost and well-known technique that can be used not only with polyester threads, but also on sequins to create designs that benefit from the embroidery and printing technologies.

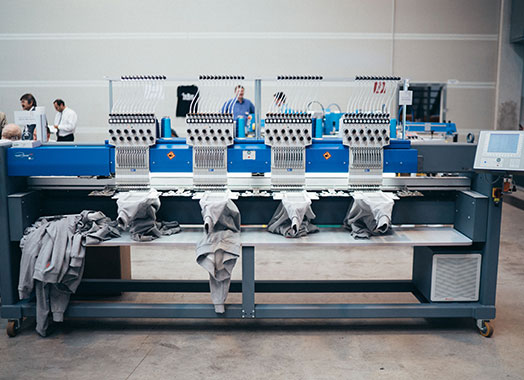

Dying yarn comes with the additional task of digitizing a design for the embroidery machine and afterwards adjusting it in a separate software for the dying process. Thy system typically only works on a single head machine, as a thread break on a multi-head machine will lead to slightly different results. In sublimation both single heads as well as multi-head machines can be used and thread breakages do not represent any issue in the process. When dying yarn one is limited to one thread thickness. In sublimation, one also has to work with polyester threads, but is open to a variety of thread thicknesses, as the design requires them. The cost of ink for the printer is lower than for the dying machine and the risk of ink drying in tubes is not relevant.

A further key point is the investment – for sublimation a heat press, a washing machine as well as a printer are required. A heat press and washing machine is often available in most companies and does not represent an additional investment.

If you are interested to learn more about sublimation, make sure you visit a ZSK training session or approach our sales colleagues to learn more about right temperatures and timing on the heat press.

SPRINT

The SPRINT series offers versatile one-head tubular embroidery machines for all operating modes such as border frame, cap and tubular.

RACER

State of the art technology – With the embroidery machines of the new series RACER, we set again the world standard for tubular embroidery machines.