ZSK – In More than 100 Years Grown into a Top Company

From a small joinery to one of the world leaders in the development and production of embroidery machines – the transformation of our company could not have been greater. After nearly 150 years we are at a point that the founder, Hermann Schroers, certainly would not have dreamed of: our company was honored in 2017 as one of the 100 most innovative medium-sized companies in Germany. Future-oriented solutions will continue to be the focus of our activities in the coming years – based on many years of experience and know-how.

Laying of the Foundation Stone: Joinery in the Velvet and Silk City of Krefeld

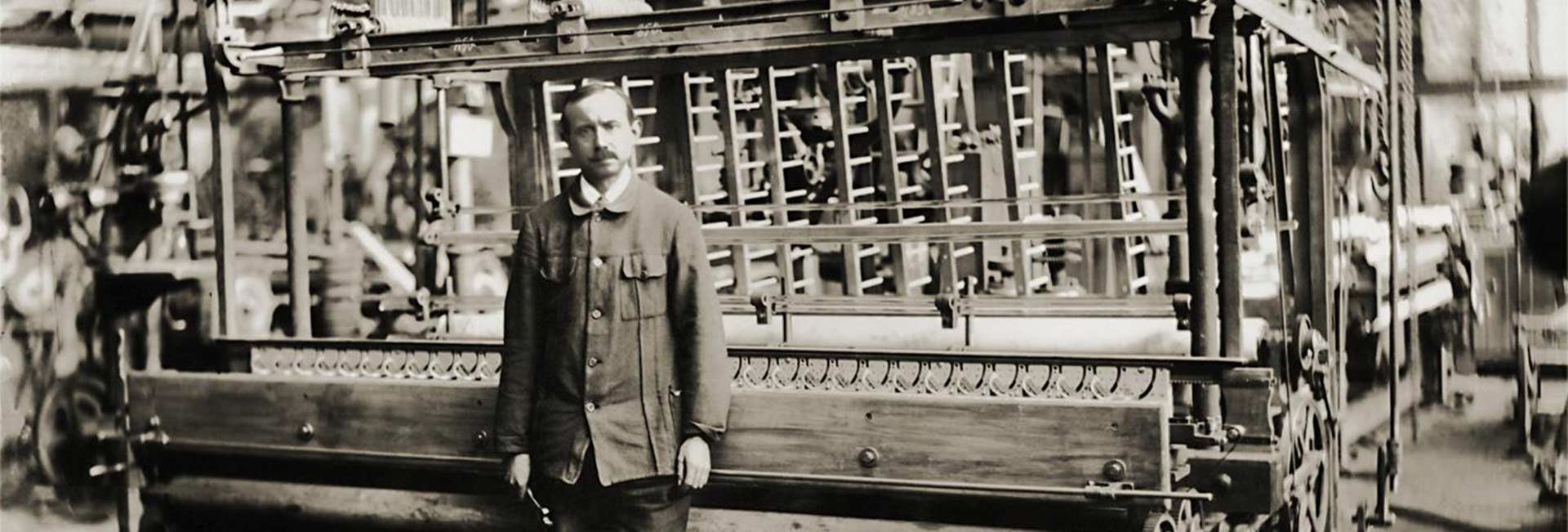

Almost 150 years ago, at the age of 22, Hermann Schröers founded a joinery in 1875 in his father-in-law's special wheels plant. He laid the foundations for today's ZSK Stickmaschinen GmbH - in the velvet and silk city of Krefeld, which is still a business location today.

Textile Machinery: Founding of Carl Zangs Aktiengesellschaft

After more than 20,000 shaft- and more than 50,000 jaquard machines produced, the company was split between the sons of Hermann Schröer and Carl Zangs after the First World War. The branch of Hermann Schröers pursued the fabrication of machine tools, while Carl Zangs emphasized the textile machinery industry and founded the machine factory Carl Zangs Aktiengesellschaft in 1920.

Reconstruction: Again Leading Position in the Field of Textile Machinery

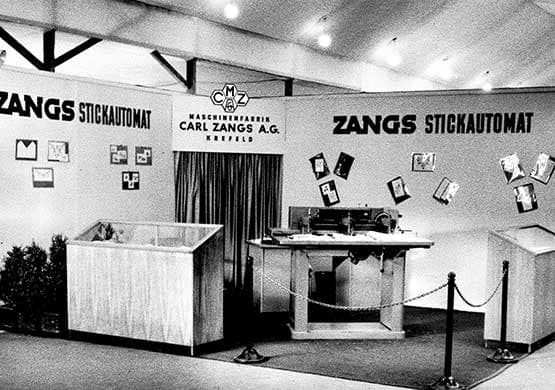

The Second World War left its mark on Carl Zangs AG. But already five years after the end of the war, all repairs were completed and Carl Zangs AG again took a leading position among the manufacturers of textile machinery.

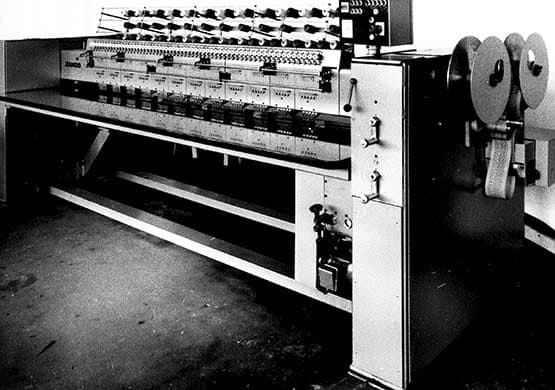

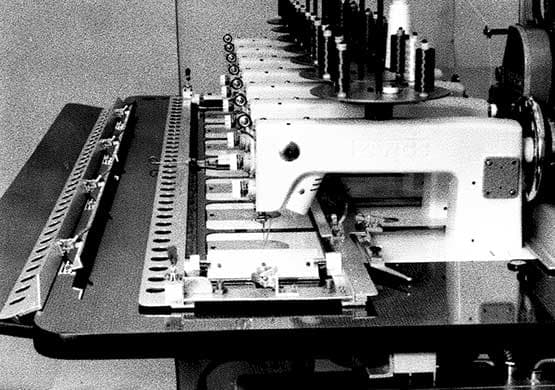

Extended Program: Production of Multi-Head Embroidery Machines

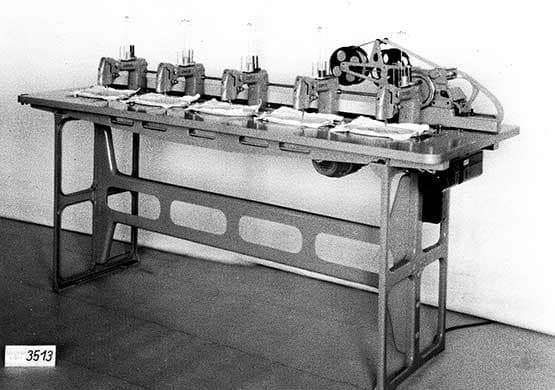

In addition to the extensive production program for weaving machines, a new product has been added to production: the multi-head embroidery machine. In its construction, Zangs used as a model the 3-head Würker embroidery machine manufactured until the end of the war in Chemnitz. The Zangs multi-head embroidery machines worked fully automatically and were controlled by punch cards. To further increase productivity, the number of embroidery heads increased successively to as many as twelve.

Premiere: Production of Shuttle Embroidery Machines

Supported by a license from the USA, the production of shuttle embroidery machines began in 1953. In 1954, the first machine with a length of 18 m, 2.10 m width and 3.60 m height with 22 t weight was presented.

Without Threading: Requirements of the Embroidery Industry Met

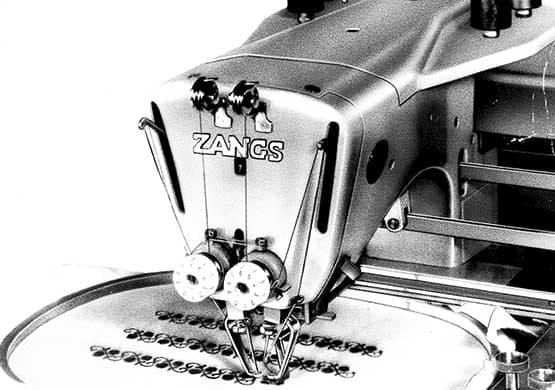

After careful development and intensive testing at the factory, Zangs started the standard delivery of the automatic rapport and color changer for shuttle embroidery machines. This novelty realized the wishful dream of the embroidery industry to be able to embroider fully automatically in different repeats and colors without threading. Entirely new ways in patterning technology and an enormously increased cost-effectiveness characterized this device.

Modular System: Success with Multi-Head Embroidery Machine

The worldwide success and high demand for the new machine types prompted Zangs to expand the shuttle embroidery machine manufacturing program. In the modular system, almost all wishes regarding machine size and degree of automation could be met. The success of new multi-head embroidery machines models as well as the high technical development level of the flat bed machines led to a considerable production expansion.

Restart: ZSK Continues Tradition

After 108 years of tradition, Zangs AG closed on November 9, 1983. The shareholders of the two leading agencies from Italy and Germany, Mr. Micheletti and Mr. Walz, took over parts of the former Zangs AG and gained skilled former employees for the re-establishment of the company, ZSK born.

Expansion with Success: Based on New Developments

Innovations such as the use of intelligent controls and sensors, specialized application software and cloud solutions have left their mark on the following years and continue to characterize our company. As a result, new areas of application in industry have increasingly been tapped and successfully expanded in recent years.

Looking Back and Forward – an Interview with Mr. Micheletti

Dear Mr. Micheletti, your family stands for a life for and with ZSK. How and when did the partnership between your father and ZSK begin?

It is very difficult to summarize a period from 1959 until today in a few sentences. I will tell you about the most important events. The “marriage” of Micheletti and embroidery machines started in the early 1950’s. Mr. Oscar Micheletti worked at company Satori as an accountant. Dr. Satori had a second company, a sock factory at the Lago Maggiore, which required his time and therefore he wanted to sell the agency business. He found no one who was interested and therefore it was decided to setup a limited partnership. Dr. Satori was the limited partner (3.000 Deutsche Mark in spare parts) with two employees as general partners. These two employees were Mr. Micheletti and Mrs. Melli. I was 14 years of age and I remember very well how many nights my father did not sleep. He was asked to decide to change from being an employee to becoming an employer. Will we succeed? What happens when there is no more demand? These were our biggest concerns. The company Micheletti KG was founded on the 1st July 1959.

You have started to work in your fathers company at a very young age and you have developed the company over all of Italy. What are your most interesting memories from this time?

After a few years Mrs.Melli decided to leave the business, as her husband had a very good income. My father had to liquidate the business, which was not very easy. Due to this my father had psychological difficulties and I was more of a moral help than a real help (even though I had started to attend a technical university). After five days of university I had to come to the company. At that time I did not even know what an invoice or a delivery note was.

We had two technicians for the support of our customers. One of our technicians became sick and my father asked for a technician from Germany (Mr. Nolden). I have driven the technician to all our customers. As the technician from Germany was very expensive for a small company like ours, I drove to Krefeld to learn in two weeks about repairs of machines. The machines at that time were rather simple. After those 14 days of training, I had to visit the customers. The training was good, but I had no experience.

It was a nice time. I was welcomed very well by our customers. A few months later our technician returned and I returned to the office. I started to look after the distribution of a different product, but I continued to look after technical issues of embroidery machines. Even in those years there were issues from time to time.

In the year 1969 the embroidery machine #1.000 was delivered to Italy (Lake Garda) to Sirmione and celebrated. My father received a wood model of an embroidery machine, as Mr. Zangs had promised my father to give the machine #1.000 as a present. When my father turned pale, Mr. Zangs told him that below the model he had fixed a credit note.

In the following years the sale of embroidery machines worked very well. The company only had one location in Milan and we had to hire six new technicians to look after customers all over Italy. The technicians came on monday morning to the office, collected spare parts for the coming week as well as their work instructions and gave feedback about the work in the previous week. Afterwards we all had lunch together and everyone went off to our customers. The technician that had to go to Tuscany had to drive for three hours. He would not go to the customer, but straight to the hotel, so we lost an entire day.

During this time embroidery and knitting was very popular. One Japanese competitor already offered multi needle machines where we only had a single needle head. We were able to show customers that loading of the machine with several needles was more time consuming than with a single needle machine. This argument worked very well and we sold many machines.

In order to service our customers well, we had to hire a technician in Carpi, who could be with customers on monday morning at eight. In 1981 we hired a sales person for the region and a lady for accounting and thread sales as well as a person for the warehouse to look after spare parts. This was the start of our location Centro Ricamo. The customers were very pleased and we decided to open further locations: Puntoricamo, Filmont, Tuttoricamo and Gammafil.

Only few people know that you and Mr. Walz have saved 1983 the survival of ZSK after Zangs went into insolvency. How did you start with ZSK in 1983/84?

After we had finished the built up phase in Italy, the shock happened and Zangs went bankrupt in December 1983 and we were without a product to sell.

I cannot recall how many train and flight trips I did to Stuttgart to meet with Mr. Walz and his advisor to find an agreement. In the end we found an agreement with Mr. Walz and Mr. Sültmann, so that we were able to receive the permission from the insolvency court to continue building multi head embroidery machines. We started with 39 people and the company ZSK Stickmaschinen GmbH was founded.

The story does not stop here. A few months later, Husquarna decided to close their factory in Schweinfurt (Meister). This factory delivered ZSK with the embroidery heads and was therefore key for the future of ZSK. After several negotiations with Husquarna, Walz and Micheletti also had to buy this company and found the company Meccanica. Mr. Walz later continued this company. Overall it was a difficult birth, but one needs to remember that ZSK had taken the best employees and the best distributors from Zangs. The company developed very well, even if at the beginning 50 % of the machines were delivered to Italy and 25 % to Germany.

A few years later ZSK Stickmaschinen GmbH was honoured to be one of the best developing companies in Germany!

In the 80s and 90s you had huge successes in Italy. ZSK was not able to built enough machines and there was not sufficient thread. Please tell us about this time.

Due to the very good situation in Italy, all of our locations had a huge stock of spare parts and whenever ZSK released a new model we were able to buy parts and boards at a one-time special price. The customers were well serviced and we constantly ordered 15 head machines, which were sold immediately.

Those years were certainly a different time than today. It even happened once that a ZSK engineer had to do the final check of a machine after it had been loaded on a truck. Everything was scarce at that time. We did not have enough technicians, frames for the embroidery machines were sold out and especially the thread was a huge problem. MADEIRA was not able to produce as much thread as we were selling. Some customers, especially those of our competitors complained to MADEIRA about us. They thought that we wanted to support ZSK customers and would not supply them with thread. Actually this was not the truth. The truth is that there was no thread – everything was sold.

We always supported the embroidery companies over ready-to-wear factories. These companies had typically their own issues and embroidery issues could best be solved by embroidery companies and specialists. Also we did not want to upset the embroidery companies. We had learned that ready-to-wear factories would sooner or later decide to outsource embroidery again, as there were such good embroidery companies.

A huge problem was the import of embroidered fabrics and clothing from East. The cost of these products was less than cost of the pure fabric from Italy. The factories started to move to Romania, afterwards to Bulgaria, Ukraine and North Africa. Many embroidery companies, especially from Veneto, brought their machines to Romania. In Timisoara they spoke the dialect from Veneto. At the beginning the companies continued buying thread in Italy, later they bought it directly in Romania.

In contrast to your competition, you have one of the largest embroidery machine spare part stock in the world. Supply of parts for machines of more than 30 years is no problem. Are still many of your customers using brown machines from the 80s and early 90s?

You have to keep in mind that many, many used machines have been sold to Turkey. This country had an economical boom for a very long time. The number of brown machines in Italy is not very high anymore. Some embroidery companies do not want to give up on the brown machines as they allow very fast change over from thick to very thin threads. During a certain time even more new machines were shipped to Turkey than to Italy.

Our warehouses are still able to supply spare parts for machines with more than 30 years of age. Sometimes we also receive international requests for such parts.

Italy has gone through difficult times in the textile industry. The last 2-3 years have shown a good recovery. What is your forecast for embroidery in Italy in the coming years?

To give a forecast today about the future is not easy. The huge amounts of clothing are produced in China. For Italy there are only exclusive products. The ready-to-wear industry is no longer in Italy, the orders are coming from other countries.

One has to see that ZSK has introduced a lot of novelties to the market to make the machines interesting for the customers such as: different sequin devices, cording device, automatic bobbin changers, application of beads, hot air cutting, embroidery of thick yarns,… Beside having only machines for the textile industry, ZSK has extended its offering to other industries.

In the automotive industry ZSK can recognize perforation and place embroidery and quilting extremely precise on seat covers, even if the material slightly shrinks in the frame. I am sure that these sectors will show very good growth in the coming years. I hope that the traditional embroidery machines Made in Germany will remain of highest quality standards and success due to their efficiency, strength and flexibility. I wish ZSK all the very best for its future.